What is the ideal coating for my pool?

Temperatures have risen and it is inevitable not to think about the comfort and refreshment provided by a swimming pool in the area of relaxation and leisure. Some people already have one installed, and think about doing maintenance or possible renovations. Others begin to specify to fulfill the dream of having the first pool ready to enjoy the sunny days without having to leave the house. And doubt that comes the most is: What is the ideal coating for my pool?

There are several patterns and styles previously observed only in internal and external areas with the beauty of HD prints and the high performance of technical porcelain tiles and their XL formats. The pieces launched in 2020 of brand Eliane Ceramic Tiles, for example, bring a variety of technologies and dimensions, ranging from 80×160 cm, 120×120 cm, 80×80 cm ao 60x60cm, with seating joints ranging from 0mm to 2mm. The products bring a new aesthetic to swimming pools fleeing the traditional green or blue tiles and tiles.

Swimming pool project explored the coral pattern of technical porcelain tiles Micron, from Eliane

The colored granites, with its rich chromatic range inspire the collection Micron, that brings to porcelain all the beauty of natural stones with the resistance and performance of ceramic tiles. This is Eliane's first polished porcelain tile for high traffic environments and swimming pools. Every detail was thought to be a sustainable and more technological option for architecture and decoration.

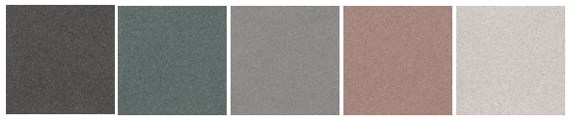

Micron has 5 different colors for finishing: black, Verde, Grey, Coral and White

Another highlight is the porcelain tile Flint, an exclusive technological innovation in Brazil. Inspiration comes from the rock of the same name, which due to its natural formation has a characteristic of high hardness and resistance. In this pattern, granules of different sizes, colors and shapes are mixed into the dough - which can be white or ivory – leaving all the lining of the body with the same effect. Thereby, maintains the same characteristic regardless of cut or finish.

I o Granilite , inspired by the ancient Italian terraces, has a granular monocolor or color feature. The aesthetics of the material gained the strength of technical porcelain tiles, becoming highly flexible and high performance. Canvas, State, Arenaria, Cosmic e Stelar are new options that follow the same technical characteristics of the other standards.

It is important to think that, like any other constructive project, the pools deserve good planning followed by a thorough execution, according to ABNT standards and manufacturers' recommendations on the ideal parts for this space.

Aline Sanches Oxy blue mesh MA 10x10cm | Eliane Ceramic Tiles

Waterproofing

The waterproofing process is extremely important from the foundations. If done correctly, the procedure will prevent the structures from being attacked by moisture, protecting them from wear and tear, cracks, fungi, reinforcement corrosion, deterioration of concrete, among other consequences.

Flexible system

The flexible system gets its name because it is able to follow the movement of structures within the limits stipulated in a project.

Membranes molded on site

- Polymer mortar, asphalt emulsion, acrylic membrane, polyurea membrane, thermoplastic resin, polyurethane membrane.

Prefabricated blankets

- Asphalt blanket, synthetic membranes

Rigid system

The rigid system is applied in places with stabilized structural load, such as buried water reservoirs and elevator shafts; and small structures

unchanged and with constant temperature, as galleries, underground and underground pools.

Tightness test

Before laying the covering, it is necessary to check that the structure is watertight (with the gross pool, without finishing) Is perfect.

For this, just close all drains and drain points on the floor, and fill the pool with water. After 72 hours, check for leaks.

Noronha safira mesh BR 75x75cm | Eliane Ceramic Tiles

CORRECT CHOICE OF COATING

There is an ideal coating for every situation. Choosing the best option for your need is crucial for the product to have the best performance and meet expectations regarding safety, maintenance and durability.

You also need to invest in a good structure. With water absorption below 1% and greater mechanical and chemical resistance, technical porcelain tiles are viable options for these environments because they have a higher performance and smaller joints, that contribute to the reduction of damage caused to joints by chemical water treatment.

2.1) Swimming pools interior

A product intended for use inside swimming pools must have special characteristics such as crack resistance (for enamelled products), chemical resistance to products used in water treatment, ease of cleaning and low humidity expansion.

Below we will indicate the necessary technical characteristics of the products for use in each of the locations indicated below:

little beach – According to NBR 10339, the depth of the foot washers / prainha cannot exceed 20cm and, obligatorily, the product to be installed needs to be COF II. Children's pool – The children's pool tank cannot exceed the maximum depth of 60cm, nor the depth of 30cm close to the edges, and the bottom slope

must be at most 8%, according to NBR 10339.

Pools for adult use – A NBR 10339 does not determine the minimum friction level for coverings intended for pools with a depth greater than 60 cm.

Obs.: All products that have a WFA use location can also be

specified in the indoor pool areas.

Pool deck – The choice of a covering for the leisure area should always be made with great care, mainly for wet environments. In addition to being an area of natural movement for people, the pool deck is also a space where children usually play and run, therefore, the product to be installed must avoid possible slips.

Eliane restricts to this area only product lines with FFO and FRO usage locations, that is, products that have slip resistance characteristics (wet friction coefficient greater than 0,40 NBR compliant 13818).

Pool Edges – The edges are the areas surrounding the pool. For greater user safety, NBR 9050 suggests that this place be coated with a rounded finish and resistant to slipping.

Cemented edges – Just like in porcelain tiles, cementitious edges also have internal and external corner finishes for 90 ° angles.

If the pool has circular or irregularly shaped corners, the edges must be acquired in original size and cut to form the desired angle. The cutouts must be made with specific disc for porcelain, and the dimension of the parts to be cut must be calculated in a project.

Grout – Grouting is a material that will remain submerged most of the time and in direct contact with chemicals used for water treatment and cleaning. Taking that into account, needs to be added to have resistance and to meet the expectations of the use, therefore, we recommend consulting the grout / coating manufacturer to see which condition is most appropriate for your situation.

The ceramic coating must be executed, not minimal, after 14 days of the mechanical protection layer or regularization (when necessary). Its surface must not show irregularities such as visible surface flaws or deformations.

AC 59 Gray Motive×59 | Java lago mesh MA 10×10 | Palladio Cinza EXT 90×90 | Bordo Palladio EXT | Canto and the Palladio Cinza A EXT | Canto and the palladium cinza B EXT 30×90 | Eliane Ceramic Tiles

IMPLEMENTATION OF THE SETTLEMENT

Before starting the installation, inspect the ceramic pieces to be laid, checking that they are all from the same reference, hue and size, and if the aesthetic effect meets the expected. Do not mix pieces of different shades and sizes in the same environment. If the project specifies the combination of different products in the same environment, make sure the size is the same for everyone.

WATCH OUT!

During the execution keep the pool covered, protecting it from the weather, mainly, rain, avoiding a future debasement!

Open time

Control the open time of the adhesive mortar. The mortar will be in good condition if, when touching the strings, fingers get dirty.

Grouting

Remove the spacers and grout, not minimal, 48 hours after the end of the settlement. Clean all joints and the surface of the laid pieces while the mortar is still fresh.

To avoid future problems, check with the grout manufacturer for the recommended time between grouting and filling the pool.